Sustainability at DBT

DBI and the Operator have established a whole-of-terminal approach to ESG issues and sustainability.

DBT is a vital link in the global steelmaking supply chain.

The high-quality coal we handle on behalf of our customers is used to build the infrastructure we all depend on, to make the products we all use, and to produce the energy on which we rely. Building on programs and initiatives already in place, DBT has developed a Sustainability Strategy – Handling with Care – a joint commitment of DBI as owner, and Dalrymple Bay Coal Terminal Pty Ltd (DBCT P/L) as operator.”

Our Approach to Sustainability

To ensure our Sustainability Strategy continues to remain relevant in a changing world, DBI and the Operator conducted a new Materiality Assessment in 2022, as detailed in the DBI 2022 Sustainability Report.

Four key pillars – People; Environment; Business Performance; and Community and Partnerships – form the sustainability framework for DBT and provide the foundation for DBT’s sustainability initiatives and programs.

People

DBI and the Operator recognise their workforces are key to a sustainable future and will be critical to their success. DBT supports the workforce through primary commitments to workplace health and safety (WHS), learning and development opportunities, and other people-centric initiatives such as flexible work arrangements.

Safety

The health and safety of those working at DBT is a key priority, whether they be employees, contractors or visitors to the site.

The Operator is responsible for the safe operation of DBT and has the primary responsibility for compliance with relevant safety legislation as the DBT operator. The Operator’s mature Health and Safety Management system (HSMS) is certified to ISO 45001 Occupational Health and Safety Management. Robust systems and processes are the foundation to the approach for the management of health and safety. The Operator is committed to continually improving its safety performance to ensure safe operations through effective risk management, including a focus on material risks. Performance goals, performance management results, management review actions as well as audit results and trends are some of the initiatives that drive continual improvement at the terminal. All workers (including the Operator’s contractors) are provided with the necessary training and inductions to perform their work safely and effectively, including how to identify risks, how to mitigate and manage them, and how to comply with the requirements of the HSMS, as appropriate. Every person who enters DBT to perform work is required to complete site inductions before commencement of work.

Environment

DBT’s location within the Great Barrier Reef World Heritage Area (GBRWHA) and proximity to residential communities brings with it a responsibility to minimise and mitigate the impact of its operations on the community and the unique ecosystem in which it operates. DBT’s Sustainability Strategy therefore focuses on advancing the protection of our reef and ecosystems, managing our resource consumption and accelerating solutions to progress climate action.

As illustrated [here], the Operator is responsible for the day-to-day operation of DBT under the OMC, including obtaining and maintaining relevant environmental approvals and licenses. The Operator holds the Environmental Authority for DBT. The Operator’s Environmental Management System (EMS) has ISO 14001 certification and is designed to ensure that the Operator strictly complies with DBT’s Environmental Authority, the OMC, and DBT’s other regulatory and environmental obligations. The Operator holds the ISO 14001 certification to ensure global best practices are met with respect to DBT’s operations. The focus of environmental management includes limiting the impact on local air quality, protecting water resources, limiting noise emissions and protecting the local habitat.

More information regarding the way each of these areas are managed can be found via the DBCT P/L website.

Terminal decarbonisation roadmap

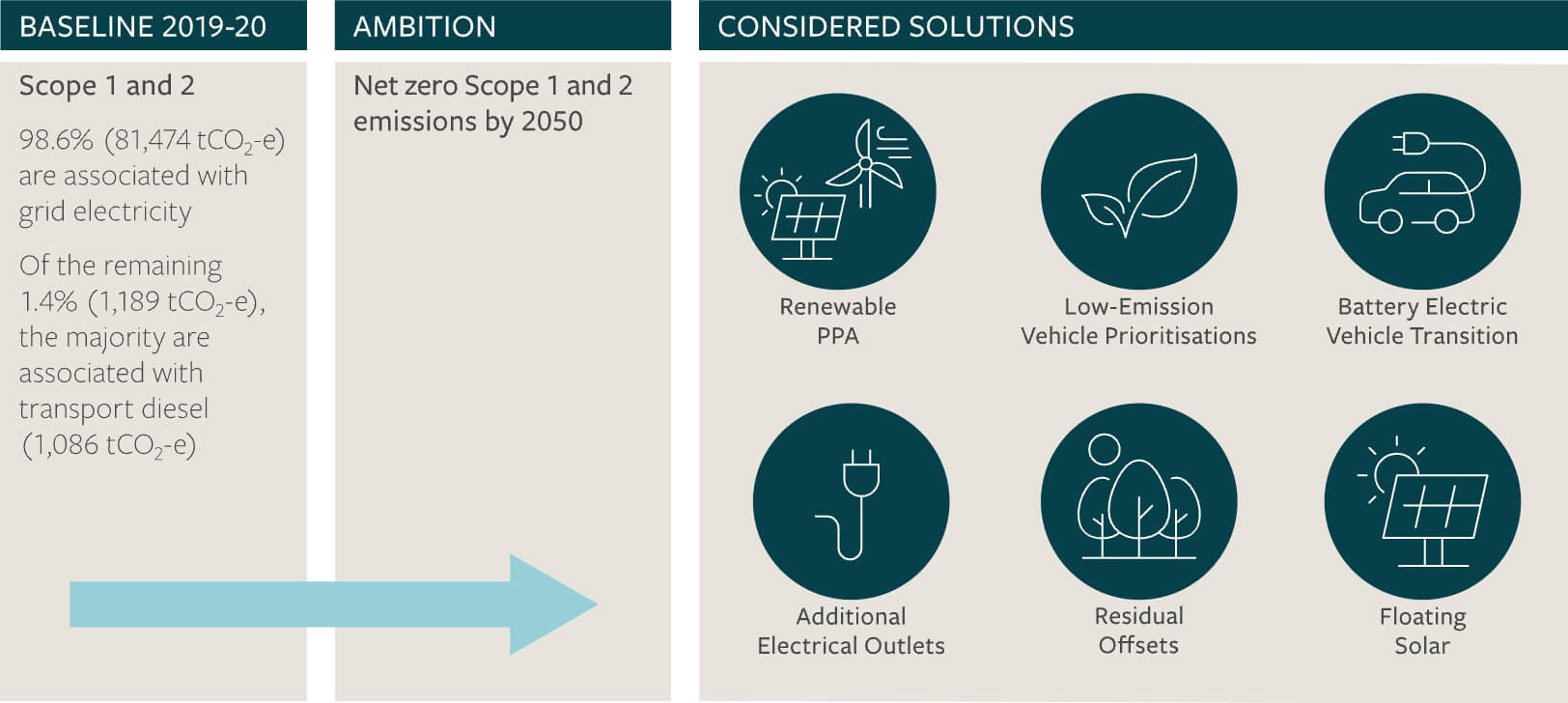

DBI and the Operator have developed a Decarbonisation Roadmap to target DBT’s material Scope 1 and Scope 2 emissions. The Decarbonisation Roadmap identifies a shortlist of six opportunities that may substantially reduce Scope 1 and Scope 2 emissions at DBT. One of these opportunities, a power purchase agreement with 100% renewable benefits in the form of LGCs, has already been secured for DBT for the period from 1 January 2023 to 31 December 2031. The remaining five opportunities will be subject to further consideration and investigation.

Business Performance

Ensuring that the terminal operates sustainably is critical to providing a viable seaborne gateway for the global metallurgical coal export trade out of the central Bowen Basin. Collaboration and communication with supply chain partners – mining companies, rail operators, ship owners and shipping agents – encourages transparency, efficiency and improved performance across the supply chain. The DBT operation supports regional economic development and growth as a major local employer and partner of local businesses.

Terminal Efficiencies

Driving terminal efficiency and maximising use of the existing footprint is a key consideration in terminal management and in supporting an efficient supply chain.

During 2022, the 3D Mapping and Automation System (3DMAS) was introduced to DBT stockyard operations. The 3DMAS improves inventory reconciliation by introducing visibility of stockpiles in near real-time 3D imaging, and increases automation of the yard machines through mapping sensors and computer processing. The Operator will continue to enhance stockyard efficiency with consideration of yard and stockpile capacity, equipment efficiency and new innovative technology.

Supply Chain Efficiency

DBT’s success relies on collaborative partnerships and communication to drive efficiency throughout its supply chain. DBT has a coordinating role in supply chain logistics to deliver coal to vessels in a timely and efficient manner. It is important that all supply chain participants can actively participate in this process to ensure the most accurate and relevant vessel and rail planning information is made available when required. DBI and the Operator have continued to lead and participate in a variety of forums that provide additional awareness and understanding among the wider supply chain stakeholder base. These forums involve all levels of supply chain participants, ranging from the people who execute day-to-day operations, to executive level representatives who are responsible for charting the supply chain’s long-term strategy.

Asset Management

Asset management is a service provided by the Operator to DBI under the OMC. The aim of asset management at DBT is for the Operator to strategically manage the maintenance, performance and end of life planning for terminal assets to optimise their whole of life contribution.

The Operator has implemented an overarching Asset Management System which sets out the foundations for managing DBT’s asset portfolio in a manner which ensures it is able to deliver against the requirements of the OMC and regulatory requirements.

Community & Partnerships

DBT is located within close proximity to a number of communities around Hay Point, as well as nearby Sarina and Mackay. Community engagement is a key pillar of the Sustainability Strategy, with DBT’s partnerships and connections with the community essential to achieving its sustainability objectives through constructive engagement with the local community.

For more information on the Operator’s Community & Partnerships visit: https://www.dbct.com.au/community

Memberships Associations:

To advance our sustainability initiatives, we value the importance of building strong partnerships with other organisations and industry associations. Some examples of the external initiatives the Operator support are listed below:

| Partnership & Membership Groups | Details |

|---|---|

| AHRI – Australian Human Resources Institute | Membership held by the Operator |

| AIM – Australian Institute of Management | Membership held by the Operator |

| ARCSOPT – Association of Resource Companies, Ship Operators, Ports & Terminals | Committee Membership held by the Operator |

| CRG – NQBP Community Reference Group for the Port of Hay Point | The Operator attend CRG meetings and are invited to provide updates periodically |

| CWG – Community Working Group | The Operator facilitates this working group |

| DCA – Diversity Council of Australia | Membership held by the Operator |

| HR2RP – Mackay-Whitsunday-Isaac Healthy Rivers to Reef Partnership | Funded Southern Inshore program since 2017 and jointly funded with DBI since 2019 Partner on HR2RP Committee position held by the Operator |

| ILCO – Integrated Logistics Company Pty Ltd | The Operator’s CEO, Steve Rae, is a Board member |

| IPA – Industry Partners Australia | Membership held by the Operator |

| JCU – James Cook University | Jewfish monitoring program in partnership with the Operator |

| MRC – Mackay Regional Council | The Operator is on the Sustainability Advisory Committee |

| MDVT – Mayor’s Domestic Violence Taskforce | Membership held by the Operator |

| NAWO – National Association of Woman in Operations | Membership held by the Operator |

| QRC – Queensland Resource Council | Service Membership held by the Operator |

| RIN – Resource Industry Network | Corporate Partnership held by the Operator |

| Tangaroa Blue Foundation | The Operator participate in the ReefClean Program |